KAPOK FIBER

- textilecoach

- Dec 30, 2020

- 3 min read

Updated: Jan 8, 2021

Introduction:

Kapok fiber is a natural, cellulosic seed fiber that is obtained from the seed pods or seed hairs of the kapok tree. cotton-like fluff obtained from its seed pods. “Ceiba pentandra” is the species, “ceiba” is the genes and “Bombacaceae” is the family of the kapok, respectively. It can grow up to a height of 50 m. It is also known as Java cotton, Java kapok, ceiba, or silk-cotton. The origin of the kapok tree is mainland Asia and Indonesia and widely distributed in tropical areas. Indonesia is one of the world's biggest kapok exporters. This plant is 60-70 m tall, and has a trunk of 3 m diameter, and has palm-shaped leaves.

The lifespan of the kapok tree is 60 years and become productive within 4 to 5 years. It yields about 330 to 400 fruits per year under optimal conditions, giving 15 to 18 kg of fiber and about 30 kg of seeds. The fiber yield is about 450 kg/ha. It produces 500 to 4000 fruits at one time, with each fruit containing 200 seeds and each tree bears 1000 to 2000 pods annually. seedpods are 10–40 cm long and 3–5 cm thick.

It is not possible to spin kapok fiber because of their short length, low volume weight, slippery nature, brittleness, fluffiness, lightweight, cannot withstand strong stresses and too inelastic nature causes poor inter-fiber cohesion. So mostly kapok fibers used in fabric blends that can be spun, making the resulting fabrics softer and more comfortable to wear. The buoyancy of kapok is about five times as great as that of cork and about three times that of reindeer hair.

Processing of kapok fiber:

Harvesting: Harvesting has to be done when a fruit is ripe. The pods are gathered when they fall on the ground or they can be cut from the tree. Seedpods are harvested by hand and closed seedpods are beaten with bamboo sticks to break hard husk and to reach fibers. When ripened, seedpods burst and the compressed fibers spread widely.

Removing hulls: Riped fruits are dried in the sunlight for removing hulls. Fibers and seeds can be removed from the ponds by hand.

Removing seeds: The seed and fiber are stirred in the basket or simple, sieve-like devices similar to drums to separate the fiber from the seed, pod debris, dry leaves, etc. So that the seeds fall to the bottom of the container where they are easily separated.

Drying of fiber: Kapok fiber is dried under the sun for three to five hours.

Bailing and packing: kapok fibers are then packed in the form of bales.

Classification of kapok fiber:

Super Fine Quality (AJK)

Fine Quality (C-Min)

Standard Quality (C-Off)

The highest quality of kapok fiber comes from Africa and Java. Lower quality of fiber comes from Ceylon and India.

Qualitative fibers are produced by only ripened kapok seed ponds. Immature fibers have low strength, inferior luster and color, and do not withstand stress during compression into bales but their appearance can be improved by fermentation in the open air, however, mechanical properties are not improved with this process.

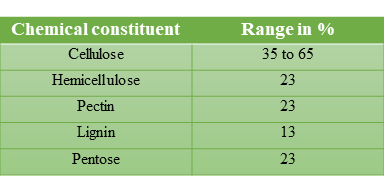

Chemical composition:

Properties:

Length: 10 to 35 mm

Diameter: 20 to 43 μm

length-to-diameter ratio (aspect ratio): 720

tensile strength: 0.84 cNdtex–1 (93.3 MPa)

Young’s module: 4 GPa

breaking elongation: 1.2%

Average linear density: 0.064tex

Moisture regain: 10%

specific density: 0.29g/cm3

c/s: oval to round

Deniar: 0.4 to 0.7

Tenacity: 1.4 to 1.74 gram/ deniar

Elongation at break: 1.8 to 4.23

Weight: This fiber is 8 times lighter than cotton by volume

Fiber color range: Ivory white to camel brown

Kapok is a quick-drying, moisture-resistant, buoyant fiber, and resilience.

It is highly flammable.

Characteristics:

Bounciness.

Slippery.

Lightweight.

Hypoallergenic.

Warm.

Hydrophobic in nature.

Excellent oil absorbency and retention capacity.

Thermal insulator.

Biodegradable.

Advantages:

It is used as stuffing for pillows, mattresses, sleeping bags, bedding, and upholstery, as insulation material, and as a substitute for absorbent cotton in surgery.

The floss has been used in life preservers and other water-safety equipment.

It is used in the construction of thermally insulated and soundproof covers and walls.

It is used in the manufacture of lifebuoys and belts, waistcoats and other naval life-saving appliances.

Kapok has also been investigated as an absorbent material for oil and acoustic insulation.

The kapok fiber once used in floatation vests and has been used as building insulation has a hollow fiber and looks like glass fiber under the microscope.

During the war, kapok was employed for insulating tanks, for lining aviation suits, for filling floats of army assault-bridges, and generally for replacing the cork wherever lightness, moisture-resistance, and floating power were needed. Disadvantages:

It is irritant.

It is highly inflammable.

The fibers are fragile and break easily.

Not suitable for weaving or spinning.

Irritant to the lungs and need extra care during work.

Comments